In industrial piping systems, every connection point is a potential risk point, especially during high-temperature and high-pressure sterilization processes. The reliability of connecting components directly determines the safety and efficiency of the entire production line.

As the critical component connecting pipelines and equipment, the design, material selection, and manufacturing process of stainless steel sterilization pot flanges directly impact the quality of sterile production in industries such as food and pharmaceuticals.

01 Product Overview

Stainless steel sterilization pot flanges are specialized pipeline connectors designed for high-temperature, high-pressure sterilization equipment. They are primarily responsible for connecting the sterilization pot to pipelines conveying steam, cooling water, and other media, serving as the core component that ensures the system's sealing, pressure-bearing capability, and safe operation.

During operation, sterilization pots create a high-temperature, high-pressure internal environment (e.g., working temperatures can reach 135°C, working pressures up to 0.3MPa).

This demands that connecting flanges possess excellent sealing performance, compressive strength, and corrosion resistance to prevent media leakage, contamination, and ensure safe and reliable production processes.

To meet different application needs, flanges come in various types, including plate flange, welding neck flange, threaded flange, and blind flange, designed to accommodate different installation requirements and piping configurations.

02 Material and Manufacturing Process

Material selection is fundamental to ensuring flange performance. High-quality stainless steel sterilization pot flanges are typically manufactured from materials such as: S30408 (304), S31603 (316L), duplex stainless steel (e.g., S22053), and special alloys (e.g., 904L, Hastelloy).

These materials offer distinct advantages in corrosion resistance, mechanical strength, and high-temperature performance based on their alloy composition. For example, 316L stainless steel, with its added molybdenum content, demonstrates superior resistance to chloride corrosion compared to 304 stainless steel.

In terms of manufacturing process, high-quality flanges typically employ forging-2. The forging process optimizes the metal's crystalline structure, enhancing material density and mechanical properties, resulting in flanges that perform more reliably under high pressure and temperature fluctuations.

Following forging, flanges undergo precision machining to ensure the flatness of connecting surfaces and sealing effectiveness.

03 Technical Specifications and Standards

Stainless steel sterilization pot flanges are manufactured according to various international and domestic standards. Common execution standards include ANSI, DIN, GB, JIS, and BS4504, among others.

These standards regulate flange dimensions, tolerances, pressure ratings, and testing requirements, ensuring products meet engineering specifications across different regions worldwide.

The product size range is extensive, customizable from DN15 up to DN6000, covering nearly all industrial application scenarios. Regarding pressure ratings, products can be supplied in various classes from 150# to 2500# or PN0.6 to PN400, based on requirements.

Flange sealing faces are available in multiple types, including Flat Face (FF), Raised Face (RF), and Ring Joint Face (RTJ), to suit different sealing needs. Surface treatment options are also varied, such as mirror polishing, mechanical polishing, or sandblasting, meeting different industry hygiene and aesthetic requirements.

04 Core Application Scenarios

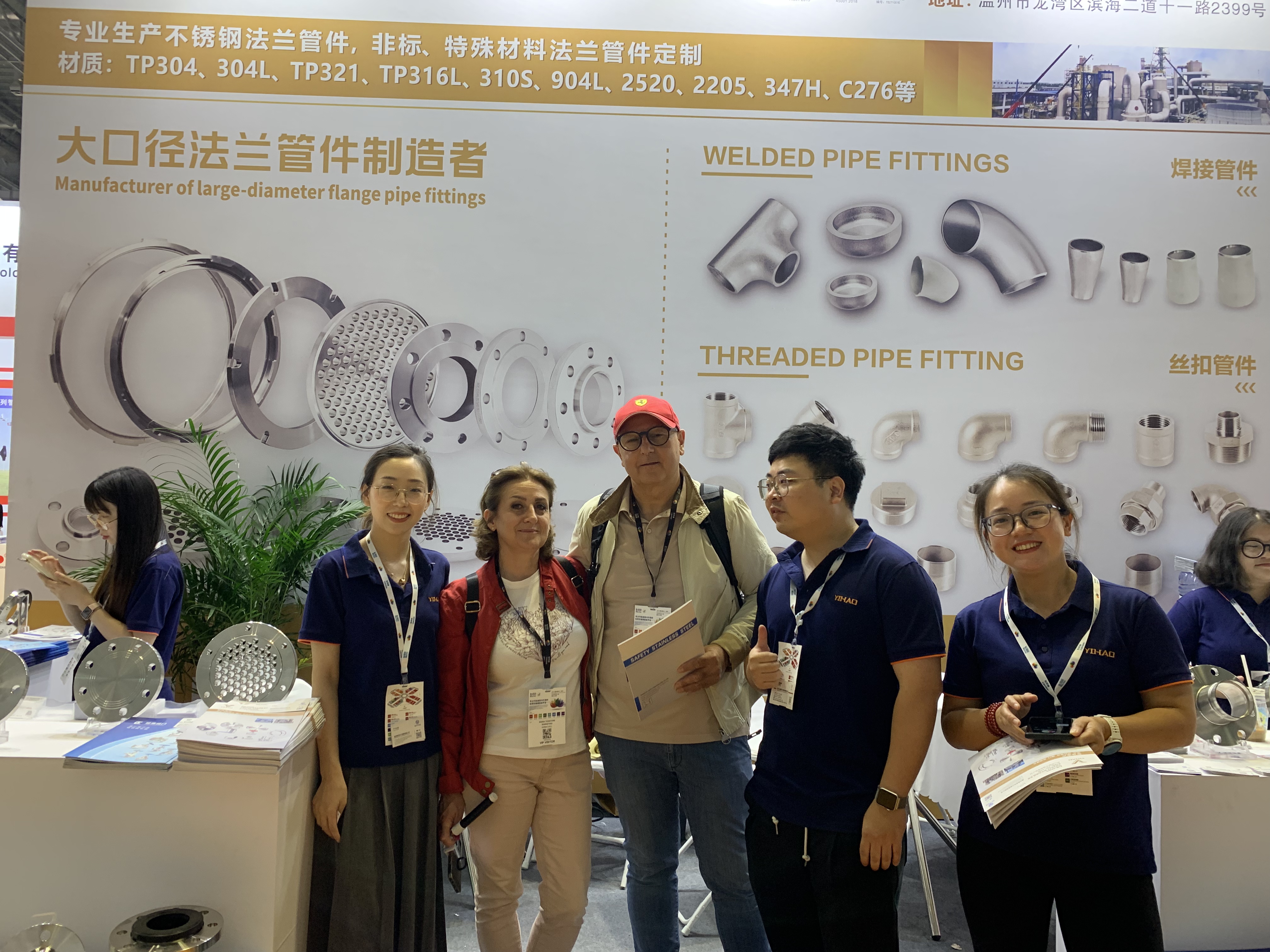

Stainless steel sterilization pot flanges are widely used in industrial sectors requiring strict sterilization and aseptic operations, serving as crucial connecting components that ensure safe production in these industries.

Within the food industry, they are used to connect various types of sterilization pots, processing products including meat, soy products, dairy, beverages, and canned goods. Whether for metal containers, glass bottles, or soft packaging, reliable flange connections are essential to ensure system sealing during sterilization.

The pharmaceutical industry imposes even stricter requirements for sterile environments. Flanges here connect sterilization equipment and clean pipeline systems, safeguarding contamination-free transfer during drug manufacturing.

In the chemical sector, these flanges are utilized to connect reactors, storage tanks, and various processing equipment, withstanding corrosion from chemical substances.

05 Core Product Advantages

Stainless steel sterilization pot flanges offer several technical advantages over standard flanges, translating directly into tangible value for customers.

First is exceptional durability. High-quality stainless steel materials combined with forging processes result in products with high hardness that are resistant to corrosion and deformation. This means longer service life and lower replacement frequency.

Second is superior sealing performance. Precisely machined sealing surfaces paired with professional gaskets maintain reliable sealing long-term under high-temperature, high-pressure conditions, eliminating leakage risks.

Furthermore, these flanges offer broad applicability. They not only comply with numerous industrial standards but can also be customized according to specific client requirements. Whether for special dimensions, non-standard pressure ratings, or unique material needs, these can be accommodated.